SafeSmart’s modular AdjustaStairs and AdaptaSpan components facilitated site access for hundreds of personnel involved in the Level Crossing Removal Project. The project is a massive undertaking that will transform the way commuters travel via rail across metropolitan Melbourne. The scope includes crossing removals and major upgrades such as new train stations, track duplication, or stabling yards accessible for all passengers on the rail network.

A part of this crossing removals project is the Southern Program Alliance (SPA), comprising of Lendlease, Acciona/Coleman Rail, Metro Trains Melbourne, and the Level Crossing Removal Project. They are a group of construction and transport industry leaders who have removed many level crossings, including Edithvale, Chelsea, and Bonbeach locations.

At these locations, excavating a rail trench to pass under the roads was needed to remove where the road crossed the railway line. However, during its removal, construction workers needed to frequently cross from one side of the trench to the other plus access into the channel, which presented a few problems.

Elevation, voids, and uneven terrain were all factors to consider. Additionally, a few conditions needed to be met for safe access around these obstacles. Access needed to be:

- – Stretcher compliant, which requires increased handrail heights and wider access stairs & walkways

- – Load rated to 2.5kPa.

- – A temporary installation.

Solutions to Rail Trench Access: AdjustaStairs & AdaptaSpan

Traditionally, this type of access would be solved with scaffold structures; however costs incurred through labour, components, and downtime for installation exceeded the budget and time constraints for the client.

After an initial consultation with SafeSmart Access, SPA enquired about the possibility of a custom solution instead. Through understanding their site conditions and budget estimates, the SafeSmart team determined that a combined solution of custom walkways, AdjustaStairs, and AdpataSpan would be a more viable option than scaffolding.

Faster to install, compliant to site conditions, and cheaper than scaffolding installations, the combined solution proved safer and more cost-effective for site access.

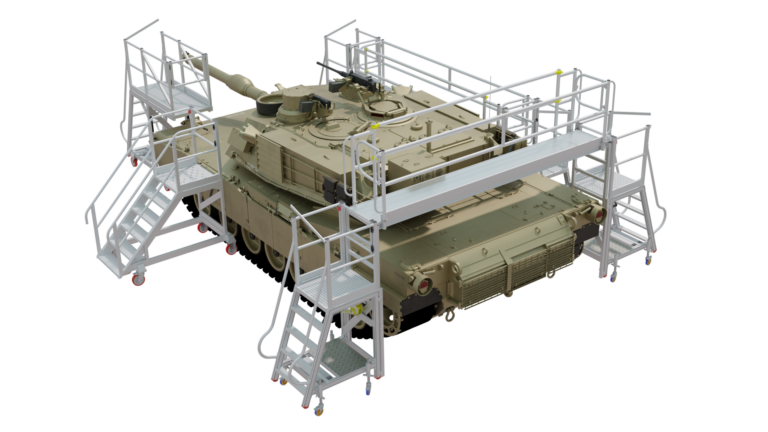

Workers could now easily access the rail trench via one staircase consisting of two AdjustaStairs and two landings, with AdaptaSpan bridging the two sides of the trench together on top. Moreover, the setup was entirely compliant for AS1657 and AS1576, as well as the needs of the site being stretcher complaint, 2.5 kPa load rating, and moveable.

The result was a fully engineered system in which SPA easily craned into position, connected together simply, and moved regularly as required. Additionally, the modular design meant that components could be independently used or linked together to cross the trench and descend into the trench off the same walkway.

Above all else, SafeSmart delivered on time with every safety concern addressed thoroughly, and a significant budget saving achieved using the non-scaffold methodology. In addition, SPA was impressed with the structure’s strength and how easily it could be moved over against stripping and rebuilding scaffold every time an access requirement was moved.

Site access is a critical component of any construction project. When site traffic needs to be diverted for safety reasons, it’s essential that a safe and compliant solution is implemented quickly and easily. SafeSmart Access has provided custom walkways and off-the-shelf solutions for many major rail projects across Australia, helping workers safely navigate the worksite while meeting all compliance requirements. And it’s as simple as contacting our team of experts who are ready to help you find the perfect solution for your next project.

Custom Design Solutions For Rail & Beyond

Every site presents its unique challenges, so it’s essential that the access solution you eventually select can solve your current access issues and adapt to any future changes in site requirements. The solution for Southern Program Alliance is just one example of how our range of standard products is integrated into custom solutions.

After clients contact us with their requirements, our team will work with you to develop a plan that best fits your needs. Our approach is to:

- Assess the budget, time, and site requirements.

- Determine suitable solutions and recommend off-the-shelf products.

- If needed, present modifications to off-the-shelf products or couple them with custom solutions.

- Move into an entirely custom manufactured product process to overcome specific issues.

SafeSmart Access has an established and growing range of standard products that can be used to create modified and custom solutions. AdjustaStairs, AdaptaSpan, and AdaptaPanels are just a few of the products we have made available for use as modular components in our range of off-the-shelf solutions.

Get in touch with us today to learn more about how we can help you create a solution that best meets your needs and budget.