A Comprehensive Analysis of Safety Measures and Best Practices

Fall arrest systems are a critical component in protecting workers from potentially fatal falls by stopping a person mid-fall and minimising the impact on their body. Working at heights poses significant risks across various industries, from construction to roofing.

In this comprehensive guide, we explore what fall arrest systems are, their importance in industries like roofing, and the best practices for ensuring safety compliance. Whether you’re looking to understand the key components such as harnesses, lanyards, and anchorage points or seeking to improve workplace safety with effective fall protection measures, this guide has everything you need to know to stay safe at heights.

By following the AS/NZS regulations and adopting a proactive approach, businesses can enhance their safety standards while ensuring operational efficiency.

What are fall arrest systems?

Fall arrest systems are designed to stop a person in the event of a fall, minimising injury by controlling the impact forces on the body. They are typically used in environments where working at heights poses a significant risk, such as in roofing, construction, or maintenance work. These systems include various components such as harnesses, lanyards, and anchorage points, all working together to arrest a fall and prevent contact with lower surfaces.

Importance of fall arrest systems in roofing

When working at height, especially roofing or installations on roofs, the risk of falling from heights is ever-present, and the consequences can be fatal. Fall arrest systems play a crucial role in safeguarding workers by mitigating the risk of serious injury or death.

Without proper fall protection, both workers and businesses face severe consequences, including injury, loss of productivity, and legal penalties. Effective fall arrest systems not only protect workers but also promote a safety-first culture that boosts overall efficiency.

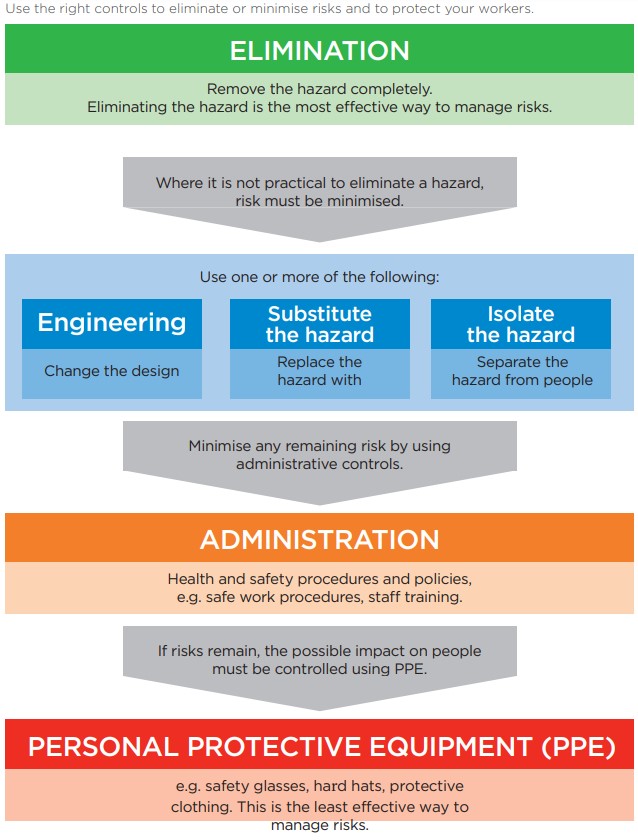

Hierarchy of Controls

The hierarchy of controls is a safety strategy used to minimise hazards. For fall prevention, it ranks methods in descending order of effectiveness:

- Eliminate the hazard (e.g., performing work on the ground).

- Substitute less risky methods or positions.

- Engineering controls such as guardrails.

- Administrative controls like training and safe work procedures.

- Personal protective equipment (PPE), which includes fall arrest systems as a last line of defence.

Components of Fall Arrest Systems

There are a range of fall arrest systems on the market that connect to rails, pivots, and anchors and consist of just as many components. But they can be broken down into three main components.

Harnesses

A full-body harness is central to any fall arrest system. It distributes fall forces over the shoulders, thighs, and pelvis, which prevents concentrated impact on a single area of the body. Modern harnesses are designed with both comfort and safety in mind, featuring adjustable straps and padded areas to reduce pressure points during long work shifts.

Lanyards

Lanyards connect the harness to an anchorage point. They often feature shock absorbers that reduce the force exerted on a worker’s body in the event of a fall. Lanyards should be inspected regularly for wear and tear and replaced as necessary.

Anchorage points

Anchorage points are critical for the efficacy of a fall arrest system. These points, which must be capable of supporting a significant amount of weight, are where the lanyard is attached. Correctly positioned and tested anchorage points ensure the fall arrest system functions as intended, halting the worker’s fall before they reach the ground or a lower level

Safety Measures for Fall Arrest Systems

Proper training for workers

Effective use of fall arrest systems depends on proper training. Workers need to be familiar with how to wear harnesses, connect lanyards, identify anchor points, and understand the importance of regular inspections. Safe Work Method Statements (SWMS) are key to ensuring this training is properly implemented.

Regular equipment inspection and maintenance

Regular inspection and maintenance of fall arrest equipment are vital. Faulty or worn-out components can fail under the stress of a fall. All elements of the system, including harnesses, lanyards, and anchors, should be checked frequently, following manufacturer guidelines.

Compliance with AS/NZS regulations

In Australia and New Zealand, fall arrest systems are regulated under several standards and regulations to ensure safety when working at heights. The key standards are the AS/NZS 1891 series. Here’s an overview of the standards which you can purchase at Standards Australia:

1. AS/NZS 1891 Series – Industrial Fall-Arrest Systems and Devices

This is the primary standard for fall arrest systems and covers the following key areas:

- AS/NZS 1891.1: Safety Harnesses and Ancillary Equipment This section specifies the design, performance, and testing requirements for full-body harnesses, lanyards, and connectors used in fall arrest systems. It includes criteria for comfort, strength, and durability.

- AS/NZS 1891.2: Horizontal Lifeline and Rail Systems It outlines requirements for horizontal lifelines and rails used to anchor fall arrest systems. This standard ensures that systems are properly designed and tested to withstand the forces generated during a fall.

- AS/NZS 1891.3: Fall-Arrest Devices This covers the design and testing of fall arrest devices such as energy absorbers, inertia reels, and other deceleration equipment. It includes requirements to ensure these devices limit the impact forces transmitted to workers during a fall.

- AS/NZS 1891.4: Selection, Use, and Maintenance of Industrial Fall-Arrest Systems and Devices This standard provides guidance on the selection, use, and maintenance of fall arrest systems, including training for workers, inspection, and proper anchorage points. It also covers rescue procedures in the event of a fall.

2. Other Key Standards and Guidelines

- AS/NZS 4488.1 and 4488.2: Industrial Rope Access Systems These standards deal with the use of rope access techniques for working at heights and provide guidance on how to perform work safely using these systems.

- Code of Practice for Managing the Risk of Falls at Workplaces (Australia) This document provides detailed guidelines on assessing risks related to working at heights, using fall arrest systems, and implementing appropriate control measures.

Best Practices for Fall Arrest Systems

Training

The risks fall arrest systems pose to workers on site cannot be understated.

As the last method in the hierarchy of controls, it is there to save someone after they fall and is fraught with risk. With this in mind, all Safe Work institutions recommend thorough training.

You can read through all chapters of the Code of Practice for Managing the Risk of Falls at Workplaces by SafeWork NSW.

Chapters 6.2 through 7.5 cover many rope and fall arrest system methodologies. Chapter 10 covers rescues and training in these areas as well.

Conducting thorough risk assessments

Before beginning any work at height, a thorough risk assessment is critical. This includes identifying potential hazards, evaluating the likelihood of a fall, and determining the severity of possible outcomes. Only after a risk assessment should a height access method be selected.

Creating a comprehensive safe work method statement

An SWMS outlines all the necessary steps for safely completing tasks involving a fall risk, including undergoing a hierarchy of control checklist. If the hazard can be eliminated, this is the best outcome; next is reducing the risk, such as doing the work at ground level or using a work platform; administrative control, such as permit systems or signed areas can be used; and finally, personal protective equipment or fall arrest systems can be used.

A SWMS includes risk assessments, hazard control measures, details on fall arrest equipment, and, in this case, rescue details and methodologies. Employers are responsible for ensuring that an SWMS is prepared and followed during any hazardous work.

Selecting the right fall protection equipment

Selecting the appropriate fall protection equipment depends on the specific task, work environment, and identified risks. For instance, some situations may require a combination of fall arrest and fall prevention equipment, like guardrails or safety nets.

Specifically for fall arrest equipment, SafeWork NSW (page 47) has a thorough checklist of:

- anchorages, including rail system

- lifelines, lanyard, shock absorber and inertia reel

- rope and wire grabs

- harness

- snap hooks and karabiners—double or triple action to prevent rollout, and

- rescue equipment.

After having a thorough understanding of the task at hand, a safety audit, and a safe work method statement, operators will be able to select the appropriate fall protection equipment.

There is no clear-cut methodology or one-size-fits-all solution for safety on site. Every situation must be assessed based on their risks.

Risks with Fall Arrest Systems

Failure to implement proper fall arrest systems can lead to severe injuries or fatalities in the event of a fall, impacting not only the affected workers but also the overall safety culture and efficiency of working at heights.

As fall arrest systems only arrest a user during a fall, users can be injured due to the forces of the arrest. As they fall and come to a sudden stop on the lifeline, they can act as a pendulum, swinging into structures. A wide range of injuries can occur, such as:

- Soft tissue damage such as strains or ligament damage.

- Breaks and fractures to bones.

- Fainting and unconsciousness.

- Renal failure.

- Suspension trauma – can cause death within 10 minutes due to restricted blood flow from the legs to the brain.

After a fall, a rescue plan needs to be acted upon from the safe work method statement. SafeWork recommends that rope access work should not occur if only one other person is available for rescue. Therefore, at least three people, including the injured, need to be trained in fall arrest system rescue.

Impacts on safety and efficiency

A properly implemented fall arrest system promotes both safety and efficiency in roofing operations. Workers can focus on their tasks knowing they are protected, while employers can avoid costly disruptions due to accidents. The key is consistent training, proper equipment use, and regular system evaluations.

When work platforms or ladders can effectively provide safety control, the use of lanyards, which can impede movement and work efficiency, is unnecessary. However, if the nature of the task specifically demands fall arrest systems and no alternative safety measures are feasible, then their use becomes unavoidable.

Summarising Fall Arrest Systems

Fall arrest systems are a vital part of workplace safety when working at heights, especially in industries such as roofing and construction. By understanding their components, adhering to AS/NZS regulations, and employing best practices like regular equipment inspections and thorough risk assessments, businesses can significantly reduce the risk of falls. Effective use of fall arrest systems not only protects workers but also enhances overall safety culture and operational efficiency

Where SafeSmart Access Comes In

While fall arrest systems play a crucial role in protecting workers from falls, they are inherently reactive solutions, only coming into play after a fall has occurred. This means that even with the best equipment and training, there is always some risk of injury due to the sudden stop or “arrest” in a fall. Workers may experience suspension trauma or other injuries caused by the forces exerted during a fall, and the complexity of rescue operations can further delay response times.

While we respect that fall arrest systems are essential for certain high-risk tasks, such as abseiling or rope access work, our approach at SafeSmart Access is to work with clients to reduce their overall risks at height wherever possible. Instead of relying solely on reactive systems like fall arrest, which only engage after a fall has occurred, we aim to prevent falls from happening in the first place through the use of edge protection and other temporary works solutions.

Here’s why SafeSmart Access is the smarter, safer alternative:

- Proactive Fall Prevention: At SafeSmart Access, we focus on eliminating fall risk altogether through comprehensive solutions like edge protection, guardrails, mobile scaffolding, and temporary work platforms. By implementing these measures, we address hazards directly, reducing the likelihood of a fall, which is a step higher in the hierarchy of controls compared to fall arrest systems.

- Tailored Solutions for Height Safety: Our team collaborates closely with clients to assess their specific work environments and recommend solutions that minimize the need for personal fall arrest equipment. For many tasks, especially in roofing, maintenance, and construction, our temporary works systems provide a safer and more efficient alternative, allowing workers to focus on their job without the restrictive nature of harnesses and lanyards.

- Enhanced Safety and Compliance: All our equipment is designed and tested to comply with the strictest AS/NZS safety regulations, ensuring that edge protection systems and temporary platforms meet industry standards for safety. By using these systems, companies can more easily adhere to compliance requirements while reducing the administrative burden associated with regular fall arrest system inspections and training.

- Increased Productivity: Working with edge protection and temporary work platforms allows for greater mobility and ease of access when compared to fall arrest systems, which often slow down operations. With SafeSmart’s solutions, workers can move freely across rooftops or elevated structures, enhancing both safety and efficiency. This leads to faster project completion without compromising worker protection.

- Reducing Rescue Complexities: One of the significant challenges with fall arrest systems is the need for detailed rescue plans in case of a fall. By preventing falls from happening through the use of physical barriers and safer access methods, SafeSmart’s solutions reduce the need for complex rescue operations, making work environments safer and less stressful for both workers and supervisors.

- Cost-Effective, Long-Term Solutions: SafeSmart Access provides flexible, reusable, and easy-to-install systems that lower the long-term costs of fall protection. Instead of investing in extensive fall arrest training and equipment maintenance, businesses can opt for a more straightforward, effective solution that safeguards workers from the start.

While fall arrest systems are invaluable for certain specific tasks, SafeSmart Access offers a proactive, prevention-first approach that minimises the need for such reactive measures. Our edge protection and temporary works solutions help clients reduce risks at height, promoting both worker safety and operational efficiency.

For organisations looking to enhance their safety culture, SafeSmart Access is your partner in building a safer, smarter workplace.