A Safety Work Method Statement (SWMS) is a crucial document used in the construction industry to outline how high-risk construction work will be carried out safely. Complying with safety regulations and ensuring a safe workplace is not just a legal requirement but also a moral responsibility. This guide will walk you through the steps of writing an effective SWMS and provide you with useful links to templates created by safe work entities across Australia.

SWMS Resources for Building, Construction, Mining, and more

New South Wales (NSW): SafeWork NSW offers detailed templates. Click here for SafeWork NSW Templates.

Victoria (VIC): WorkSafe Victoria provides a versatile template suitable for a range of high-risk construction activities. Click here for Worksafe Victoria Templates.

Queensland (QLD): Workplace Health and Safety Queensland offers resources for various construction tasks. Click here for a Queensland Worksafe Guide.

Western Australia (WA): Commerce WA provides guidelines and templates for creating an SWMS in line with local regulations. Click here for a template from the Western Australia Government.

South Australia (SA): SafeWork SA offers resources for drafting SWMS, ensuring compliance with local safety standards. Click here for a template.

Tasmania (TAS): WorkSafe Tasmania provides templates and guidance for creating an SWMS, suitable for the Tasmanian construction industry. Click here for a list of resources.

Australian Capital Territory (ACT): WorkSafe ACT offers guidance notes, ensuring that construction activities are carried out safely and in compliance with ACT regulations. See all guidance notes for ACT here.

Northern Territory (NT): NT WorkSafe provides resources and templates to help businesses create SWMS tailored to the unique requirements. See the SWMS template here.

Use these links to find the right safety work method template for where you are conducting your work.

Understanding Work Safety Method Statements or SWMS

An SWMS is a document that sets out the high-risk work activities to be carried out at a workplace, the hazards arising from these activities, and measures to control the risks. It is a practical tool to help workers and supervisors implement and monitor the control measures to ensure high-risk work is carried out safely.

Identify High-Risk Activities: The first step is identifying any high-risk construction work as defined by the Work Health and Safety Regulations. This includes activities like working at heights, demolition work, or working near overhead power lines.

Consultation: Engage with workers, health and safety representatives, and contractors involved in the work. Their input is invaluable in identifying hazards and developing practical control measures.

List the Tasks: Break down the project into individual tasks. For each task, describe the step-by-step process to complete the work safely. Be clear and concise.

Identify Hazards and Risks: For each task, identify the potential hazards. Consider the environment, equipment, materials, and work methods. Analyzing past incidents and near misses can also provide insights into potential risks.

Develop Control Measures: For each identified hazard, determine how you will control the risk. Apply the hierarchy of controls – elimination, substitution, engineering controls, administrative actions, and personal protective equipment.

Review and Update: An SWMS should be a living document. Regularly review and update it to reflect any changes in the work process, equipment, or environment.

Communication and Training: Ensure that all workers are aware of the SWMS. They should understand their roles and responsibilities and be trained in the control measures outlined in the document.

Monitoring and Compliance: Regularly monitor the work to ensure compliance with the SWMS. Adjust the controls if necessary and record any changes made.

What are the Variations in Safety Work Method Statements Across Industries

Safety Work Method Statements (SWMS) are tailored to address the specific risks and safety procedures of different industries. Each industry has unique hazards and operational practices, necessitating customized approaches in their SWMS. Let’s explore how SWMS may vary across various industries:

Construction Industry: Typically, the focus is on high-risk activities such as working at heights, using heavy machinery, and handling hazardous materials. The SWMS in construction needs to address specific risks like falls, electrical safety, and equipment operation.

Manufacturing Industry: Here, the SWMS might concentrate on machinery operation, handling of raw materials, and workplace ergonomics. Specific attention is given to the risks associated with production lines, equipment maintenance, and hazardous chemicals.

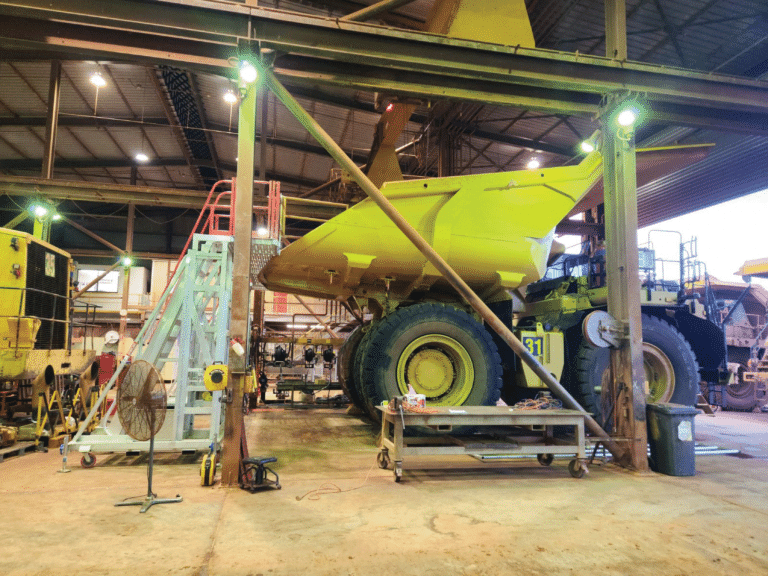

Mining Industry: Given its high-risk nature, the SWMS in mining includes measures for underground safety, handling of explosives, and machinery operation. It also addresses environmental hazards like dust control and extreme weather conditions.

Transportation and Logistics Industry: Here, the emphasis would be on vehicle operation, loading and unloading goods, and managing fatigue. The SWMS would also cover the risks associated with handling hazardous substances.

Agriculture Industry: The focus would be on the safe operation of farming equipment, handling of livestock, and exposure to pesticides and other chemicals. It also includes measures for working in outdoor environments.

In Summary

The preparation and maintenance of a Safety Work Method Statement (SWMS) is not just a regulatory requirement but a fundamental aspect of ensuring safety in high-risk work environments. It serves as a roadmap for identifying potential hazards and implementing effective control measures. The significance of an SWMS lies in its ability to adapt and respond to various situations – whether it’s the onset of a project, changes in the work environment, the aftermath of incidents, updates in safety information, or the introduction of new personnel.

An SWMS is a living document, evolving as the work environment changes. Its effectiveness hinges on its relevance and accuracy, reflecting the current state of the workplace and the nature of the tasks at hand. Regular reviews and updates are crucial in maintaining its effectiveness.

In essence, an SWMS is a cornerstone of a proactive safety culture. It emphasizes the importance of foresight in safety planning and the value of continuous improvement in safety practices. By diligently preparing and updating an SWMS, businesses not only comply with legal requirements but also demonstrate a commitment to the well-being of their workforce, ultimately fostering a safer, more responsible, and more productive work environment.