- Please choose product options by visiting Heavy Duty Plant Access Platform.

For Any Plant Equipment of Any Shape or Size

Heavy Duty Plant Access PlatformFor Any Plant Equipment of Any Shape or Size

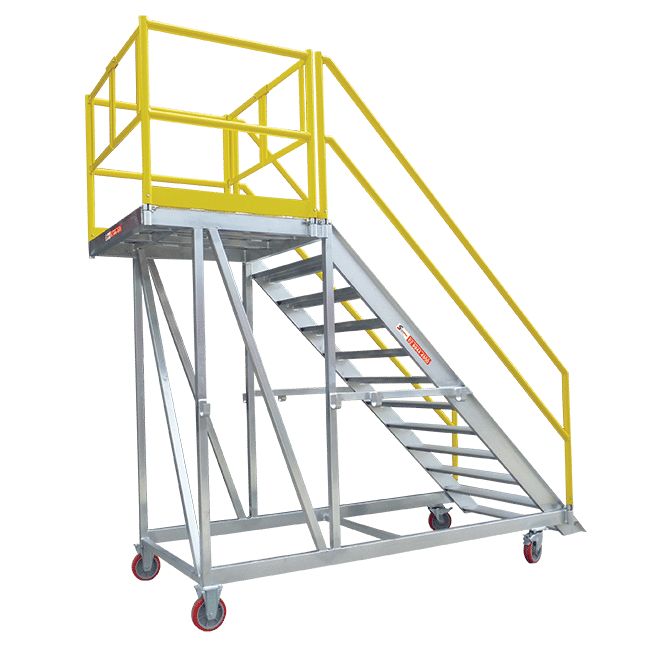

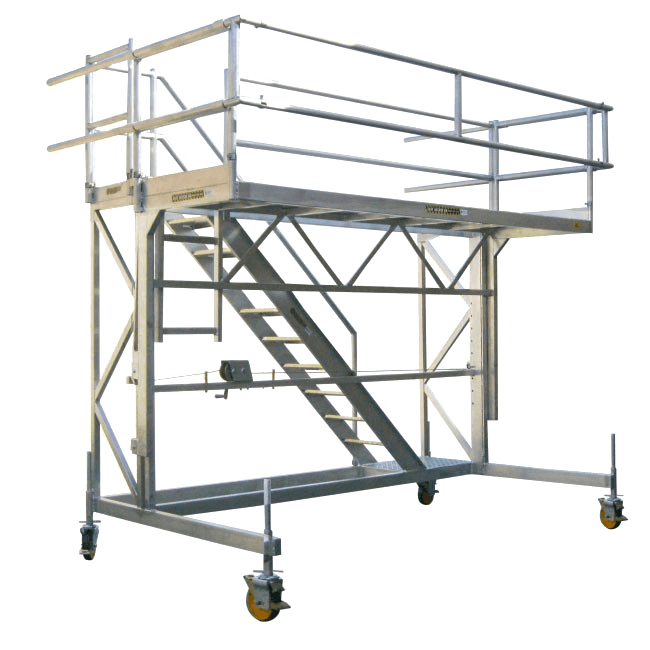

Heavy Duty Plant Access PlatformDesigned for heavy industry applications, the Heavy Duty Plant Access Platform addresses workspace issues around plant maintenance at height. In order to meet the desired requirements, this platform needed to have 45-degree angle stair access for carrying tools, high visibility handrails for onsite safety requirements, and a cantilever out the front to allow them to get right up against the plant equipment.

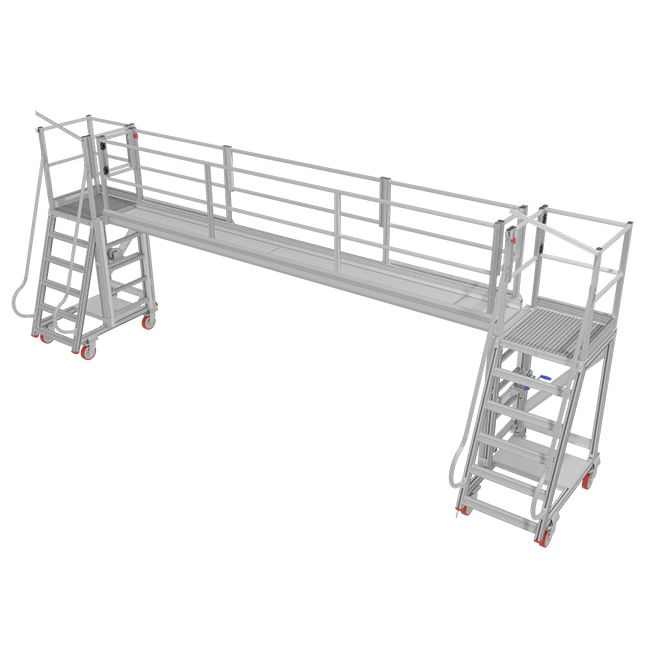

This resulted in the creation of the Heavy Duty Access Platform, inspired by our Super Maintenance Platform and Cantilever Platform, this versatile platform is a must have on any mine site. This platform can be used for various maintenance tasks such as, mechanical repairs on fixed plant machinery, access for valve/pipework maintenance and for access to haul trucks/dozers and loaders, to name a few.

When the unit is not deployed, SafeSmart incorporated a quick-release system so that the guardrail could be removed for easier storage. The client requested we deviate from our standard ‘SafeSmart red’ to the specified high-visibility yellow, as per their onsite safety requirements.

Safety and Efficiency

Prioritising worker safety, the Heavy Duty Plant Access Platform features a self-closing gate and is fully cross-braced, adding to the rigidity and stability of the structure. The platform is also equipped with heavy-duty castors that swivel and lock, simplifying relocation and secure placement regardless of the terrain. Originally designed for loading and unloading trucks, its robustness lends itself well to a broad spectrum of heavy-duty vehicles, machinery, and maintenance scenarios.

Usage Scenarios

Here are some scenarios where the Heavy Duty Plant Access Platform can significantly improve workplace safety and productivity:

- Maintenance and Repair: Its adjustable height and stable platform make it ideal for performing maintenance and repair operations on large plant equipment.

- Loading and Unloading: Constructed with functionality in mind, it simplifies the process of loading and unloading heavy items onto trucks and other vehicles while ensuring worker safety.

- Mining and Construction Sites: The rugged design can withstand the harsh conditions of mining and construction sites, providing reliable support for workers and equipment.

Additionally, the versatility of the platform aligns well with various industries seeking a reliable solution for safe access to heavy-duty machinery. From agricultural to logistics sectors, the Heavy Duty Plant Access Platform addresses the direct need for a safe and efficient workspace.

- 45 degree stairway access enables you to keep one hand free for carrying tools.

- Four large swivel/brake castors to allow for easy relocation by a single operator

- Built tough, non slip perforated deck and aluminium frame

- 300mm Cantilever feature allows you to get right up and into your desired work area.

- Powder coated guardrails in safety yellow

- 200mm Swivel/braked castors

- SWL 500kg

Designed for heavy industry applications, the Heavy Duty Plant Access Platform addresses workspace issues around plant maintenance at height. In order to meet the desired requirements, this platform needed to have 45-degree angle stair access for carrying tools, high visibility handrails for onsite safety requirements, and a cantilever out the front to allow them to get right up against the plant equipment.

This resulted in the creation of the Heavy Duty Access Platform, inspired by our Super Maintenance Platform and Cantilever Platform, this versatile platform is a must have on any mine site. This platform can be used for various maintenance tasks such as, mechanical repairs on fixed plant machinery, access for valve/pipework maintenance and for access to haul trucks/dozers and loaders, to name a few.

When the unit is not deployed, SafeSmart incorporated a quick-release system so that the guardrail could be removed for easier storage. The client requested we deviate from our standard ‘SafeSmart red’ to the specified high-visibility yellow, as per their onsite safety requirements.

Safety and Efficiency

Prioritising worker safety, the Heavy Duty Plant Access Platform features a self-closing gate and is fully cross-braced, adding to the rigidity and stability of the structure. The platform is also equipped with heavy-duty castors that swivel and lock, simplifying relocation and secure placement regardless of the terrain. Originally designed for loading and unloading trucks, its robustness lends itself well to a broad spectrum of heavy-duty vehicles, machinery, and maintenance scenarios.

Usage Scenarios

Here are some scenarios where the Heavy Duty Plant Access Platform can significantly improve workplace safety and productivity:

- Maintenance and Repair: Its adjustable height and stable platform make it ideal for performing maintenance and repair operations on large plant equipment.

- Loading and Unloading: Constructed with functionality in mind, it simplifies the process of loading and unloading heavy items onto trucks and other vehicles while ensuring worker safety.

- Mining and Construction Sites: The rugged design can withstand the harsh conditions of mining and construction sites, providing reliable support for workers and equipment.

Additionally, the versatility of the platform aligns well with various industries seeking a reliable solution for safe access to heavy-duty machinery. From agricultural to logistics sectors, the Heavy Duty Plant Access Platform addresses the direct need for a safe and efficient workspace.