Extended Reach Dozer Platform

Extended Reach Dozer Platform

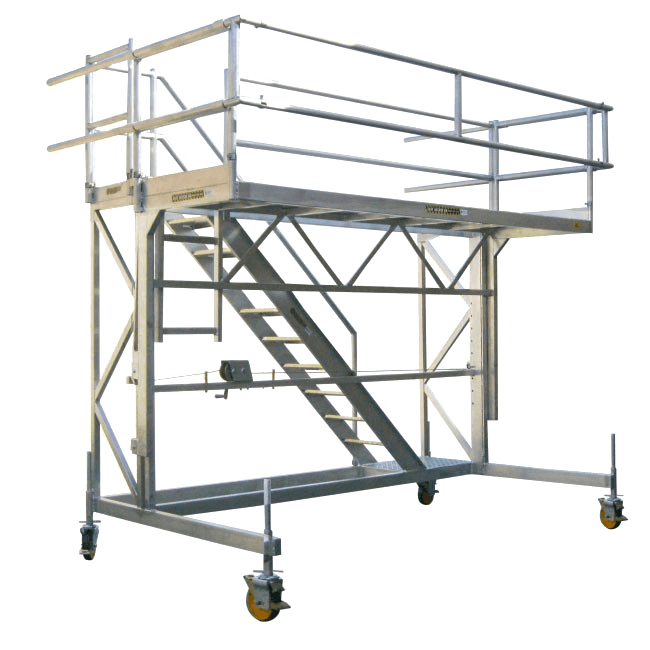

Safety and effectiveness are paramount in heavy equipment maintenance. SafeSmart Access’s Extended Reach Dozer Platform is meticulously developed to overcome the common industry challenge of engine bay accessibility. The platform’s generous cantilever length and strategic design allow workers to bypass the tracks altogether, granting safe passage directly to the engine compartment.

Safety and Efficiency

This unparalleled access is achieved while upholding rigorous safety standards. The platform includes support legs for even distribution of weight under the push arm, paired with counterweights for a robust working load capacity. This ensures that maintenance personnel can operate securely on the platform’s edge without hazards. The addition of solid rubber castors and heavy-duty machine jacks facilitates easy repositioning by a two-person team, optimising workflow and reducing downtime.

Usage Scenarios

- Regular maintenance and service tasks on D11 dozers

- Adaptable to fit the dimensions and requirements for D10, Komatsu 375, or Komatsu 475 dozers

- Any setting requiring a comprehensive and safe solution for dozer engine service access

With the creation of the Extended Reach Dozer Platform, SafeSmart Access delivers a bespoke solution catering specifically to the needs of the heavy machinery industry. This innovative approach to dozer maintenance not only advances safety but also significantly enhances service team efficiency.

- 2.1mL cantilever deck for unimpeded engine bay access

- Support legs designed to fit under the push arm for extra stability

- Counterweights under the stairs for a 225kg Safe Working Load (SWL)

- Covers the entire bay width, eliminating the need to reposition during service

- 200mm solid rubber castors and machine jacks for easy mobility

- Specially tailored for servicing D11 and adaptable for D10 or Komatsu 375/475 Dozers

- Extends beyond the push arm and track for optimal servicing reach

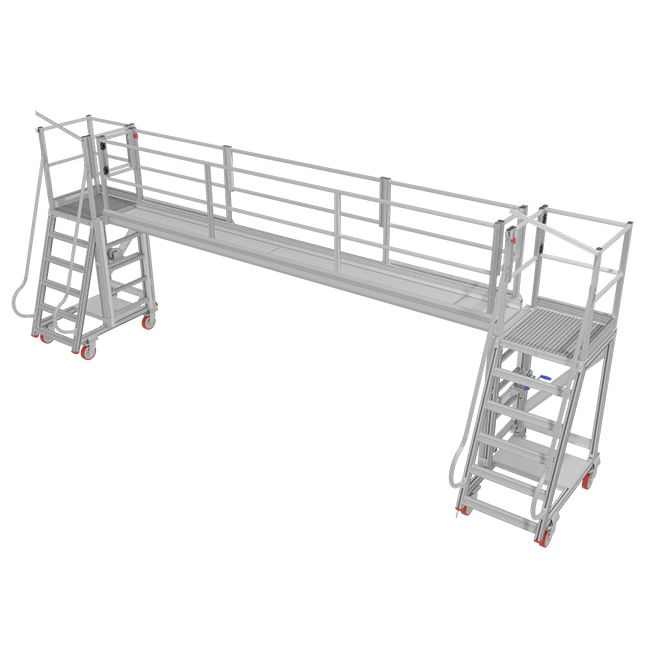

- Pair of LH and RH platforms for simultaneous access to both sides of the engine bay

Safety and effectiveness are paramount in heavy equipment maintenance. SafeSmart Access’s Extended Reach Dozer Platform is meticulously developed to overcome the common industry challenge of engine bay accessibility. The platform’s generous cantilever length and strategic design allow workers to bypass the tracks altogether, granting safe passage directly to the engine compartment.

Safety and Efficiency

This unparalleled access is achieved while upholding rigorous safety standards. The platform includes support legs for even distribution of weight under the push arm, paired with counterweights for a robust working load capacity. This ensures that maintenance personnel can operate securely on the platform’s edge without hazards. The addition of solid rubber castors and heavy-duty machine jacks facilitates easy repositioning by a two-person team, optimising workflow and reducing downtime.

Usage Scenarios

- Regular maintenance and service tasks on D11 dozers

- Adaptable to fit the dimensions and requirements for D10, Komatsu 375, or Komatsu 475 dozers

- Any setting requiring a comprehensive and safe solution for dozer engine service access

With the creation of the Extended Reach Dozer Platform, SafeSmart Access delivers a bespoke solution catering specifically to the needs of the heavy machinery industry. This innovative approach to dozer maintenance not only advances safety but also significantly enhances service team efficiency.