Safe Roof Access Systems for the Rail Maintenance Machinery

Adjustable Roof Access PlatformSafe Roof Access Systems for the Rail Maintenance Machinery

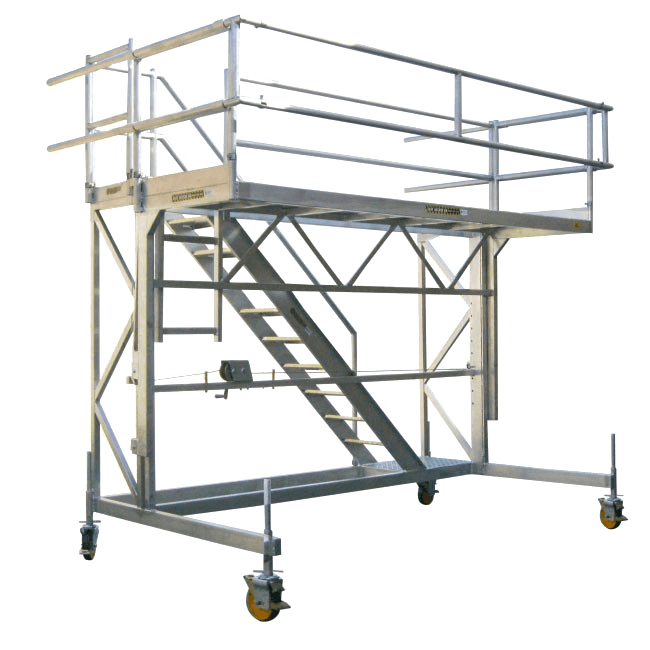

Adjustable Roof Access Platform- A solution for installation of HVAC systems and roof sections on the machinery.

- Adjustable Height Platform from 2.625 to 4.0m.

- Raised swaged decking material for superior grip in greasy conditions.

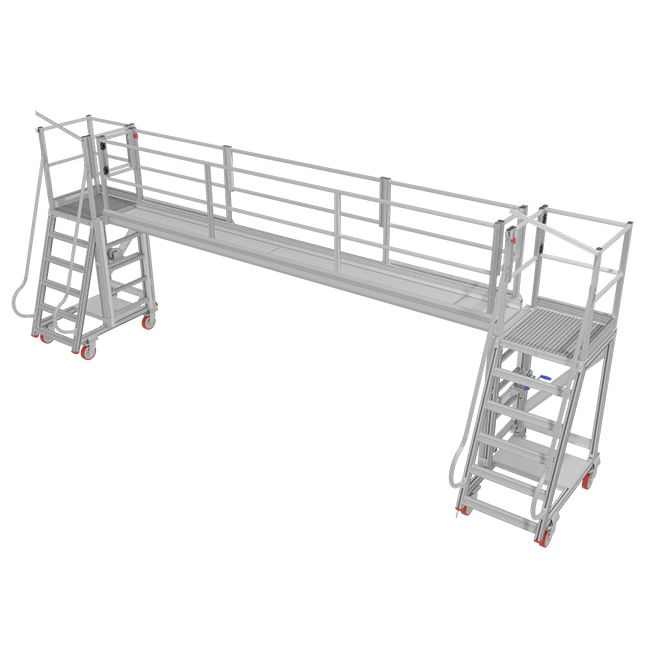

- Guardrail frame and telescopic guardrails connect across the roof of the rail maintenance machinery to create an edge protected work surface on the roof.

- Manufactured from 6261 T6 Extrusion and 5251 H32 Plate.

- 70 degree access stairs, 45 degree option available.

- Handrail, midrail & toeboard to all sides.

- Large pnuematic foam filled tyres for easy roof access across rail tracks.

- Wind down jacks for levelling and braking.

- Foam buffers to protect machinery at all contact points.

Originally designed for a client in St Mary’s, Sydney, which is the leading provider of track machinery in Australia and New Zealand. For routine maintenance, this platform allows for safe access with adjustable height and telescopic guardrails to suit varying machines and applications.

The Adjustable Roof Access Platform, catered for train roof maintenance, exhibits a 1m² cantilevered design that enables mechanics to navigate the locomotive’s rooftop with confidence and stability. Its predominant feature is the full surround guardrails at the top and mid-level, fortified by telescopic support that attaches directly to the locomotive roof, minimizing any risk of falls or unstable footing during maintenance operations.

This roof access system is designed for leading track machinery providers. It features adjustable height, telescopic guardrails, and crane lifting points for versatile applications. It complies with AS1657:2018 with a 500kg SWL.

Crafted from lightweight aluminium, the platform is easily maneuverable alongside the train by workshop mechanics, using wind-down jacks to position themselves for the 70-degree ascent securely. Upon reaching the top, operatives pass through a lift-up gate onto the platform and then through a step-through gate to gain full access to the locomotive’s roof. The surrounding large hooped rails that extend from the cantilevered platform provide a safe enclosure for maintenance personnel as they perform their tasks.

Safety and Efficiency

The Adjustable Roof Access Platform substantially increases both safety and operational efficiency for train maintenance. Aurizon has reported substantial improvements in these areas since incorporating the platform into its locomotive maintenance routine. This easy-to-deploy, stable platform is an integral part of the maintenance workflow, ensuring that tasks are carried out with minimum disruption and maximum safety.

Usage Scenarios

- Railway Maintenance: For routine inspections and repairs on various train models, providing secure access to roof-mounted components.

- Rail Vehicle Manufacturing: Assists in assembly and quality checks during railcar manufacturing, ensuring worker safety at every stage.

- Transit Authority Operations: Facilitates safe access for transport lane mechanics responsible for maintaining city and cross-country train fleets.

- Rail Infrastructure Companies: Delivers a dependable platform for companies servicing the rail industry, mitigating the risks associated with working at heights.

For railway industry professionals needing reliable train roof access solutions, this Adjustable Roof Access Platform is a testament to Safety and Efficiency in motion. With a focus on user safety, easy maneuverability, and versatile application, it is the ideal product for any organization looking to enhance its train maintenance protocols.