In our latest example, we explore how SafeSmart Access greatly improved work and safety at BHP’s Mt Arthur mining site.

The case study shows how our Reduction audits on existing scaffold use, along with smart planning, modern products, and the following of strict safety rules, led to big improvements in how quickly and safely work can be done.

In Summary:

The case study focuses on SafeSmart Access’s successful intervention at BHP’s Mt Arthur coal mining site located in the Hunter Valley, New South Wales, Australia.

The core challenge was to diminish reliance on traditional scaffolding structures without compromising safety or accessibility within the mine’s fixed plant areas.

Through meticulous planning, innovative product selection, and adherence to stringent safety standards, SafeSmart Access introduced a range of specialized access solutions that significantly enhanced operational efficiency and safety.

The initiative not only reduced the need for scaffolding, but also streamlined maintenance processes, thus offering a profound impact on the site’s operational dynamics.

Table of Contents

Scoping Scaffold Hazards

The challenge at hand for BHP’s Mt Arthur site was multi-faceted but centred around one primary objective: to reduce reliance on existing scaffold layout without compromising safety or accessibility within fixed plant areas.

The Mt Arthur coal site, managed by BHP, is nestled in the Hunter Valley region of New South Wales, Australia, and represents a significant hub for coal extraction and processing.

With the necessity for safer, more efficient means of access around the plant, especially during crucial maintenance phases like shutdowns, BHP’s fixed plant team embarked on a mission to find a solution that could meet their specific needs .

Goal Orientation

The primary goal was to enhance safety and operational efficiency by implementing a more stable, permanent solution to access requirements around the plant.

First a scaffolding audit was conducted to identify where, and what the structures were being used and how efficient they were.

Solution: Scaffold Elimination

With the challenge firmly outlined, SafeSmart Access stepped in to devise a comprehensive solution tailored to BHP’s specific needs. The project involved meticulous planning and collaboration between BHP representatives and SafeSmart’s team of access specialists.

The proposed solution was multi-faceted, encompassing a range of innovative access products designed to meet the unique demands of the mining environment. A key outcome was to eliminate scaffolding, reduce working from heights and safety risks from the following areas:

1. Laydown Areas for Truck Unloading

2. Wash Plant – DNR Coupling Access

3. Crushers and Crusher Teeth Access

4. Crushing/Screening Station Monorail Access, and Hanging Clamp and Chain Block

5. General Access around Workshop Areas and Vehicles

Removing Scaffold Structures with Innovative Solutions

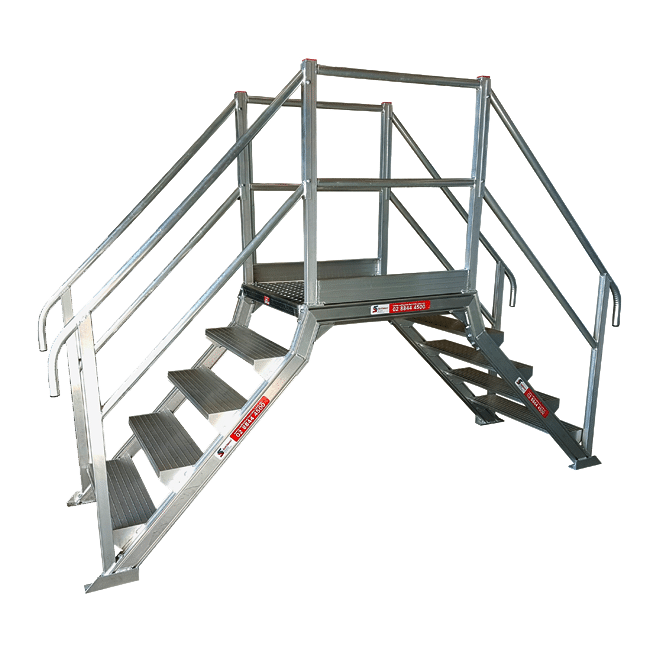

The crux of the solution lay in a suite of specialised access equipment, including the SafeLoader, Cantilever Access Platform, Super Service Stands, SMP’s, Desksurfer Maxi, Custom Conveyor Platforms, Modular Stepover, and Single Ladder.

Delivery

The delivery phase involved meticulous planning and coordination to ensure minimal disruption to the site’s day-to-day operations. Given the scale of the Mt Arthur site and the critical nature of its operations, SafeSmart Access worked closely with BHP’s team to schedule scaffold decommissioning during optimal times, ensuring that the implementation of these new access solutions did not hinder productivity. On delivery, each product has a series of documentation and instructions attached. These thoroughly detail the Safety, Assembly, and Operations (SAO) and maintenance of the products as both physical and digital copies. Where necessary, training is provided for the operations, anchoring, or further installation of the solutions provided on site.More by SafeSmart

Through Life Support

Following the successful implementation of SafeSmart Access’s solutions, the focus shifted to ensuring these solutions provided lasting value. SafeSmart Access offers comprehensive through-life support, encompassing maintenance, inspection, and training services to ensure that each product remained in optimal condition and that staff were fully trained in their safe and effective use.

This ongoing support is crucial in maintaining the integrity of SafeSmart platforms over time, ensuring that they continue to offer the highest levels of safety and efficiency in line with BHP’s operational needs.

Results

The impact of SafeSmart Access’s solutions on BHP’s Mt Arthur site was profound. The platforms facilitated easier and safer access around the facility, significantly decreasing reliance on scaffolding and simplifying maintenance processes.

The client expressed immense satisfaction with the outcomes, praising the efficacy, safety, and efficiency of the platforms and the comprehensive service provided by SafeSmart Access.

For boots on the ground, crews could continue safely working unimpeded by the new height access solutions. Without the need for regular inspections or dismantling, crews on site could get on with their work safer and more effectively.

Why Reducing Scaffold Saves More Than Just Costs

Opting for tailored solutions such as work platforms or mobile stands over traditional scaffolding for industrial, construction, or mining sites presents several advantages, particularly in the context of current Australian regulations and safety standards. These height access alternatives enhance workplace safety through features like guardrails, non-slip surfaces, and improved stability, significantly reducing the risk of accidents.

Moreover, they offer unparalleled efficiency and flexibility, allowing for quick adjustments and mobility across different site areas without the time-consuming setup and dismantling associated with scaffolding. Scaffolding requires ticketed installers, inductions, and regular scaffold inspections during the time the structure is erected.

The adaptability of an adjustable work platform solution is crucial in meeting the dynamic demands of construction and mining projects, ensuring workers can access various parts of a site with ease.

Furthermore, these tailored solutions are not only cost-effective due to their durability and reusability across multiple projects but also align with stringent Australian safety regulations, aiding in compliance and avoiding potential fines.

Collectively, these benefits underscore a shift towards prioritising safety, efficiency, and sustainability in Australia’s industrial sectors, marking tailored solutions as a superior choice over traditional scaffolding methods.

Key Takeaways

This case study underscores the importance of tailor-made access solutions in enhancing safety and operational efficiency within the mining industry.

By adhering to top-tier safety standards and focusing on bespoke, durable solutions, SafeSmart Access has set a new benchmark in the field, demonstrating the potential for innovation to drive substantial improvements in both safety and productivity for all unique project needs.