Enhanced Maintenance Safety Has Landed

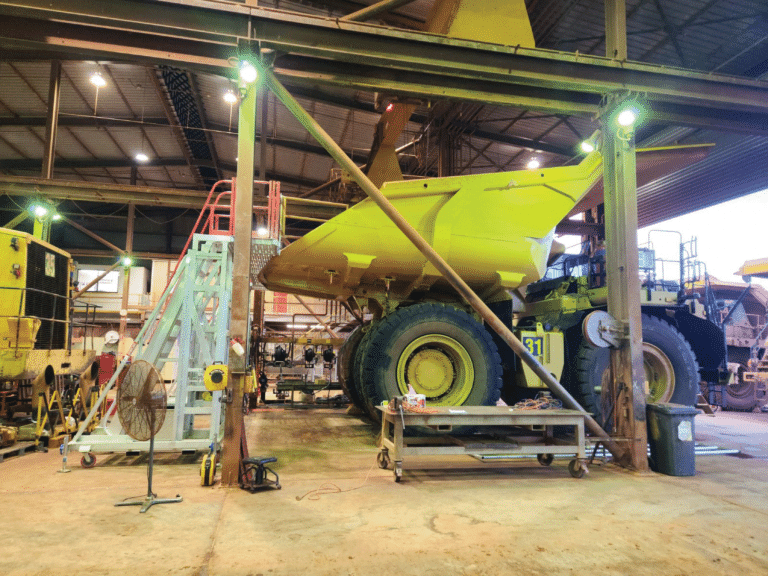

Maintenance of vehicles and other modes of transport and combat machinery is an essential element of an effective defence force. Of course, forces like the ADF do this to a tee. But height access equipment provider SafeSmart Access see room for more improvement for safety and efficiency around the maintenance workshop and out in the field.

That’s why SafeSmart are engaging with the ADF and other forces from Asia and Indo-Pacific region at Land Forces 2016 on September 6-8.

Land Forces, held in Adelaide this year, is a premier land defence exhibition and land defence forum. And SafeSmart will be there to present solutions to what is often a silent factor in machinery maintenance: personal injury in maintenance facilities, particularly when working at height.

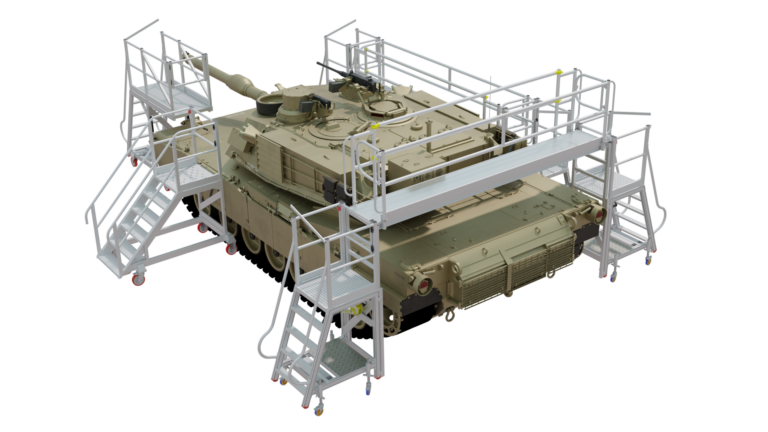

SafeSmart director Greg Hales is looking forward to contributing to the improvement of defense effectiveness. “We are reaching out to the Department of Defence and defence contractors, to show them a more efficient and safer way to access machinery, aircraft, vessels and vehicles during builds and maintenance.”

Naturally, defence forces would pretty much have the procedures and efficiency aspect of maintenance sorted. But a more safety-regulated work environment normally found in civil businesses is now a presence in the military. And the equipment required to adhere to compliance is only seeping into the military.

“It makes sense,” said Greg, “that any risk to mechanical or technical personnel poses a subsequent risk to the machinery and those who operate it. If the maintenance workshop experiences downtime through injury, it affects the quality of the servicing. Obviously, when dealing with such sophisticated machinery that the defence forces use, the better the access and safety, the more accurate and confident the job carried-out.”

And this type of workshop infrastructure setup translates into the field. Besides compliance, having the best maintenance facilities in remote or temporary off-base zones becomes perhaps even more crucial.

“When the environment is unfamiliar, and there’s a possibility of military engagement, there’s even less room for error in maintenance,” says Greg. “Access equipment should be also portable enough, robust enough and fast to erect and tear down when time is tight and conditions are challenging. To protect your support crew is to protect the protectors.”

And any access equipment provider worth their salt Is not only reactive to the needs of its client, but also proactive. With forecasts of new acquisitions, the opportunity is there to have access equipment custom designed and deployed to base when the machinery arrives.

Greg is looking forward to continuing SafeSmart’s already well-established relationship with defence stakeholders through events such as Land Force. And the development of new combat machinery is what keeps his company on its toes with building the next innovation in height access, fall protection and the like. “We are readily available to be brought in as consultants to deliver a maintenance methodology to workshops like those in the ADF that is both efficient and safe.”

SafeSmart Access can be found at stand 3J6.