Demand More from Your Scaffolding

There have been only a handful of developments in scaffolding in its long history of existence. The introduction of aluminium is the most notable innovation in this time; it has provided lightweight manoeuvrability paired with strength, saving contractors millions of dollars due to increased speed of installation and easier handling.

So the same technologies and designs since the aluminium era have been accepted as the norm and the optimum point to which innovation can be stretched. But the increase in competition for contracts means that build deadlines are getting tighter by the year, and contractors are more aware of how much their non-building activities can affect the bottom line.

To keep up, you need to review your efficiency in areas beyond just the building process. So how does a contractor get more efficiency from something as fundamental as scaffolding, for example?

Whether it is aluminium or steel, some scaffold manufacturers are looking closer and deeper at the seemingly insignificant components of a height access system to further enhance efficiency, configuration options and load bearing capabilities.

The Critical Connection

The rosette, or ‘node’ point in a scaffold system is a critical connector point for assembling scaffold. And they bear a great amount of weight, concentrated on a comparably small point. Traditionally, as per the Kwikstage system’s star design, these attachment points feature four connection options, to construct scaffolding with components at a standard angle of 90° from each other. But with more adventurous architecture, these systems often struggle to get the contractor close enough to the structure to work safely.

An Innovation Solution

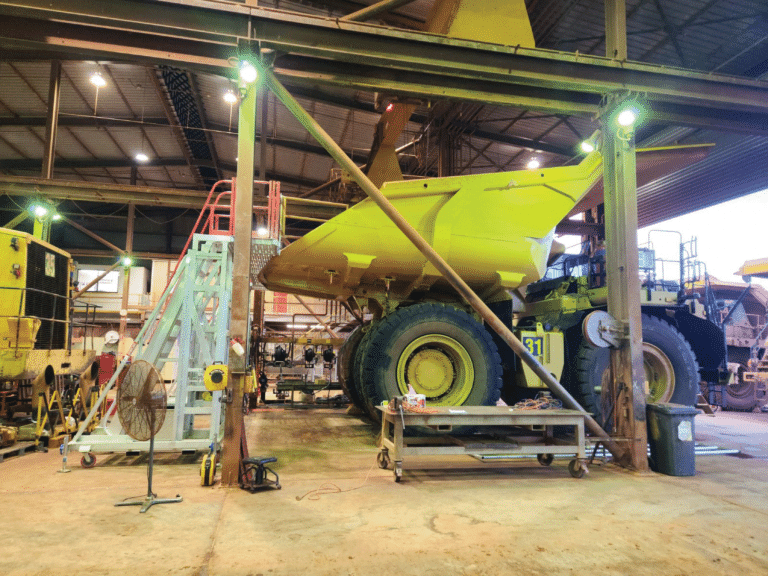

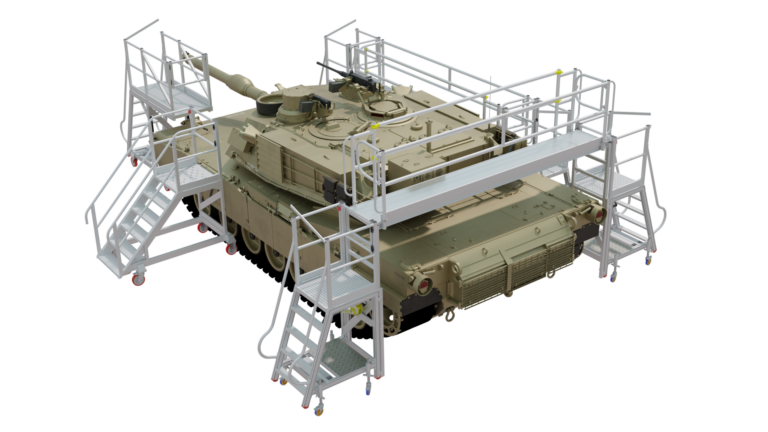

Australian company SafeSmart Access have rectified this. Their rosette—on their Proscaf product—is circular, featuring eight holes as attachment points for any type of component. This array of connection points also allows for a greater degree of angle options, so scaffolding can be erected closely to more irregularly-shaped or rounded structures such as oil refinery tanks, silos and the like.

Proscaf: Quicker than Kwik

Any contractor knows that time spent erecting scaffolding can often eat into the build time. A project needs its tradies up high safely as soon as possible, working on meeting completion deadlines and contributing to getting to the next contract quickly.

SafeSmart Access’ Proscaf is 50% faster to erect than a comparable Kwikstage scaff. For example, what would normally be a 145-minute install time for Kwikstage would be only 60 minutes for Proscaf. And this is without cutting corners on quality. In fact, along with increased build speed, the system adds more benefits.

Take a Load

The Proscaf rosette can also bear a greater weight than the Kwikstage system. Despite using high grade steel, the Proscaf system is approximately 40% lighter than Kwikstage, reducing installation time even further; fewer contractors are required to handle and install, due to Proscaf’s smarter component designs, which work through thorough engineering and physics knowledge rather than just brute materials strength. What does this mean? Well, greater load capacity means additional contractors up on the structure getting the job done faster.

So What’s the Big Picture?

In the end, investigating further into what type of scaffolding system you use can help to grow your business greatly. It’s one of those common overheads that contractors employ and take for granted all too easily. Kwikstage has enjoyed a large market segment for many years now and in Australia in particular, it is a default choice. But contractors would be well-advised to look further into other options that increase productivity even further. SafeSmart’s Proscaf does this. To break it down, Proscaf’s stats, compared to systems such as Kwikstage, are:

- 50% faster to erect

- 40% lighter than similar competitive options

- 21% fewer components = fewer contractors required to install

- 56% reduction in labour costs

- 52% reduction in transport costs

- 42% reduction in maintenance costs

The Result?

Let’s not fluff around here. Compared to Kwikstage, Proscaf has the potential to increase a contractor’s earning by up to 200%.