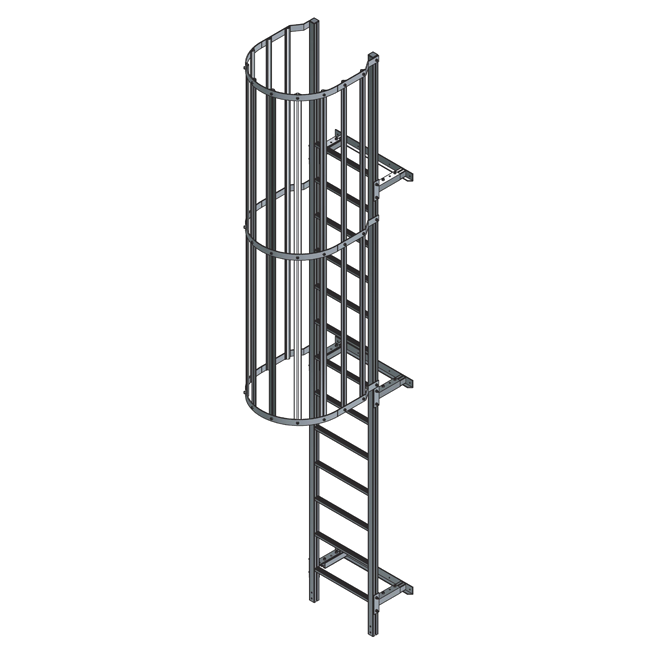

Design Your Own Safe Modular Silo Ladder

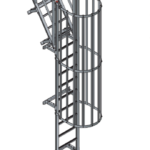

Aluminium Silo Ladder

Design Your Own Safe Modular Silo Ladder

Aluminium Silo LadderSelecting the correct components for your Caged Ladder requirements;

1. Length of the Ladder;

a. We have a range of available lengths listed.

b. The height of your ladder is measured from access point to access point + 1m. For example, say you are accessing a mezzanine level where the floor is 3m above the lower level, the length of ladder needs to be 4m

(3m + 1m = 4m).

c. Select the closest length from the list of available lengths, slightly longer if the exact length is not available so this can be cut down to suit the application.

d. If the length you require is longer than the available lengths, select the combination of lengths that leads to the least offcut and least number of joins required.

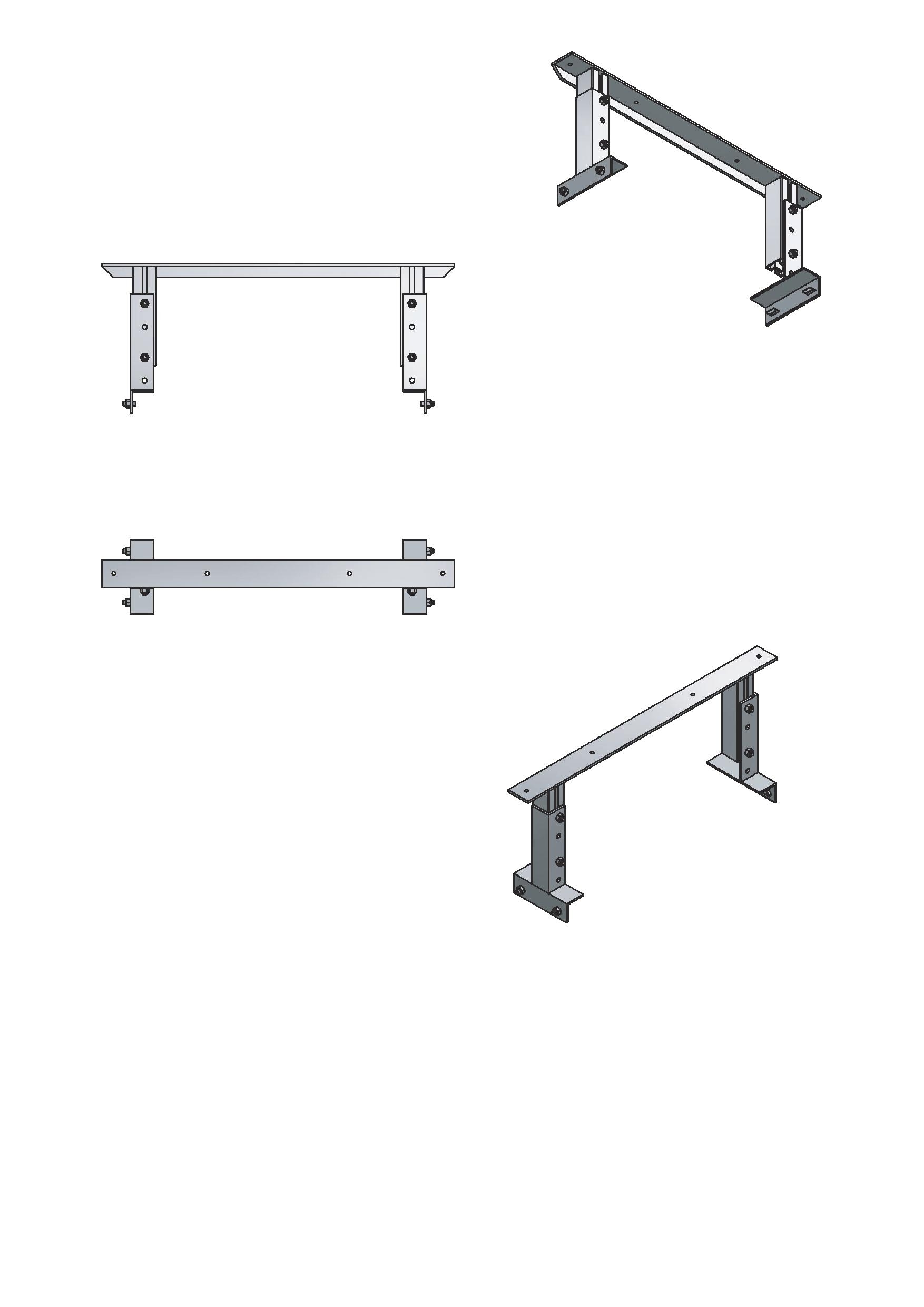

2. Joining/Mounting Hardware for the Ladder;

a. If you ladder length is longer than the available lengths and 2 or more sections are required to be joined together, you will required the SKU: 210268 – Silo Ladder Spigot Set (including hardware). One set is required per additional ladder section.

b. The ladder is mounted to the support surface with the use of SKU: 210200 – Silo Ladder Wall Mount Bracket. These are required at either end of the ladder and then every 3m along the length of the ladder from the bottom position. For a 3.6mL ladder, you will require 3 brackets.

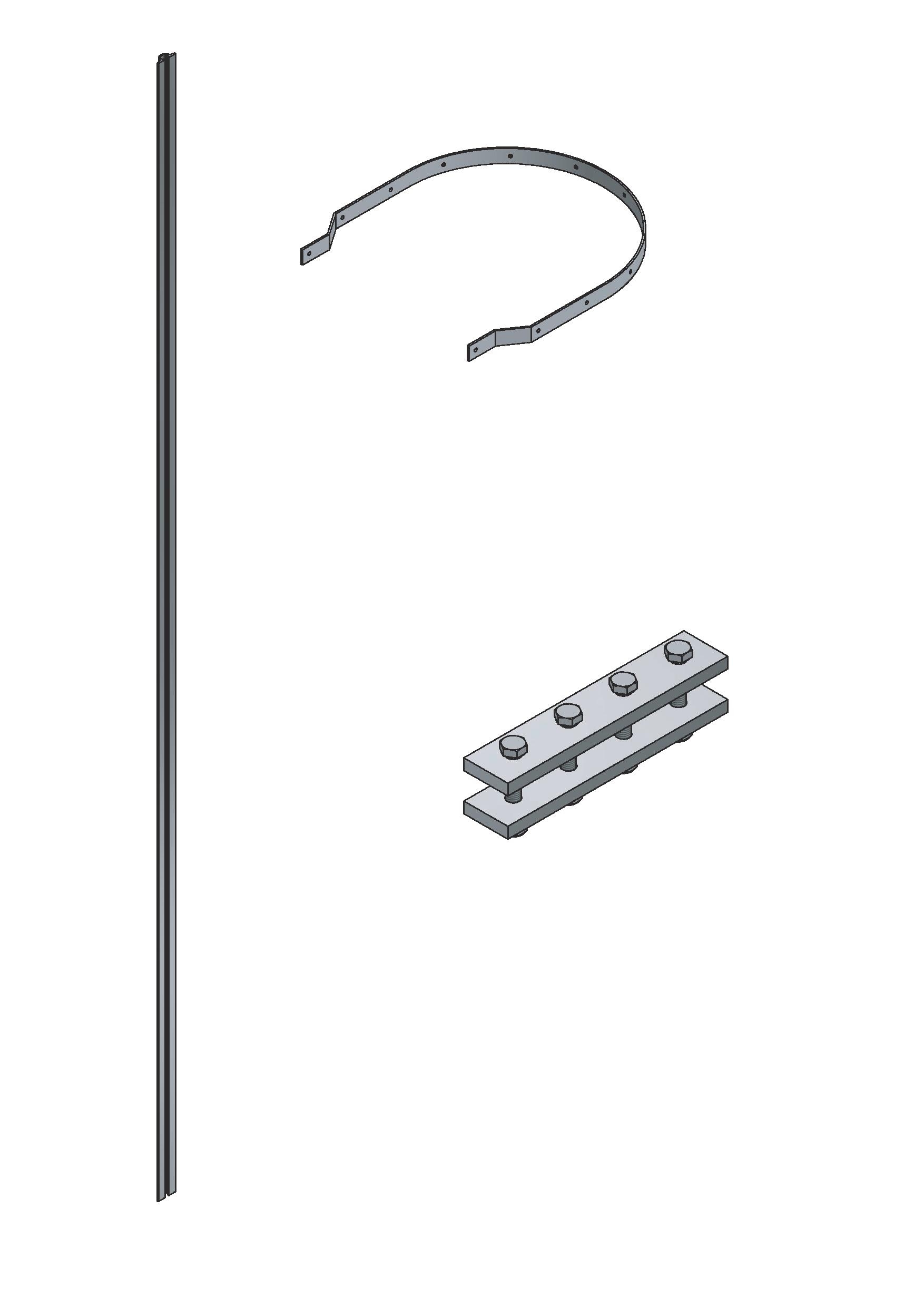

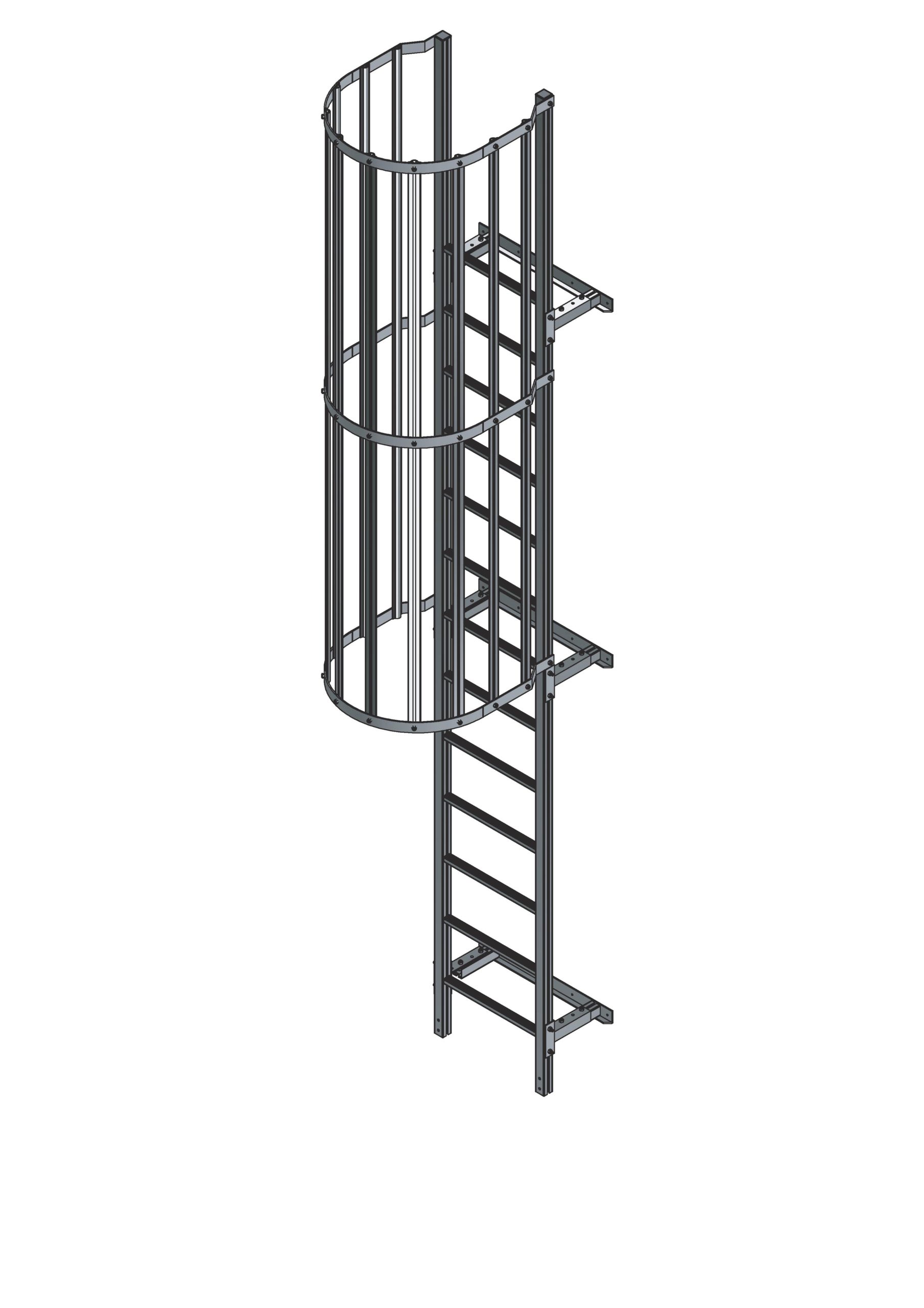

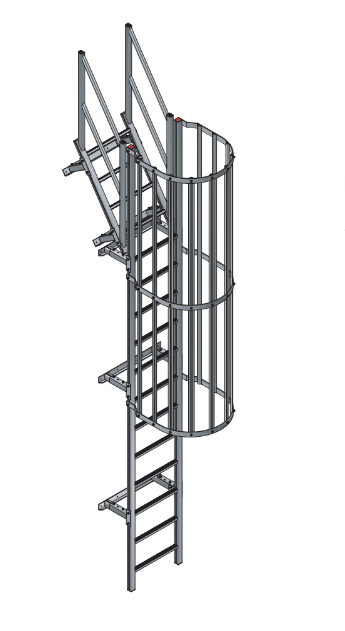

3. Cage Components for the Ladder;

a. To comply with Australian Standards, the cage of the ladder needs to be positioned so that there is 2.1m of clearance between the bottom of the cage and access surface that personnel will be using to get onto the ladder. This is to ensure head height clearance for the user.

b. Additionally, the cage needs to extend 1m up above the upper access point.

c. To calculate this, using the mezzanine scenario as previous where the mezzanine level is 3m above the lower level; the length of the cage needs to be 3m + 1m – 2.1m = 1.9mL cage.

d. With this calculation complete, now calculate the number of hoops required to create the cage frame SKU: 210267 – Silo Ladder Hoop (including hardware). These are required top and bottom of the cage and then spaced every 2m from the bottom of the cage. In the case of the above calculation where the cage length is 1.9m, 2 hoops will be required.

e. Now calculate the Cage Extrusion required, SKU: 210266 – Silo Ladder Cage Extrusion /metre. As per the description this is supplied per lineal metre. There are 10 ‘slats’ around the hoop that form the cage. The calculation of the lineal metres of slats required is as follows, the length of the cage required (i.e 1.9m) multiplied by 10, this means 19LM of cage extrusion is required (1.9m x 10 = 19m).

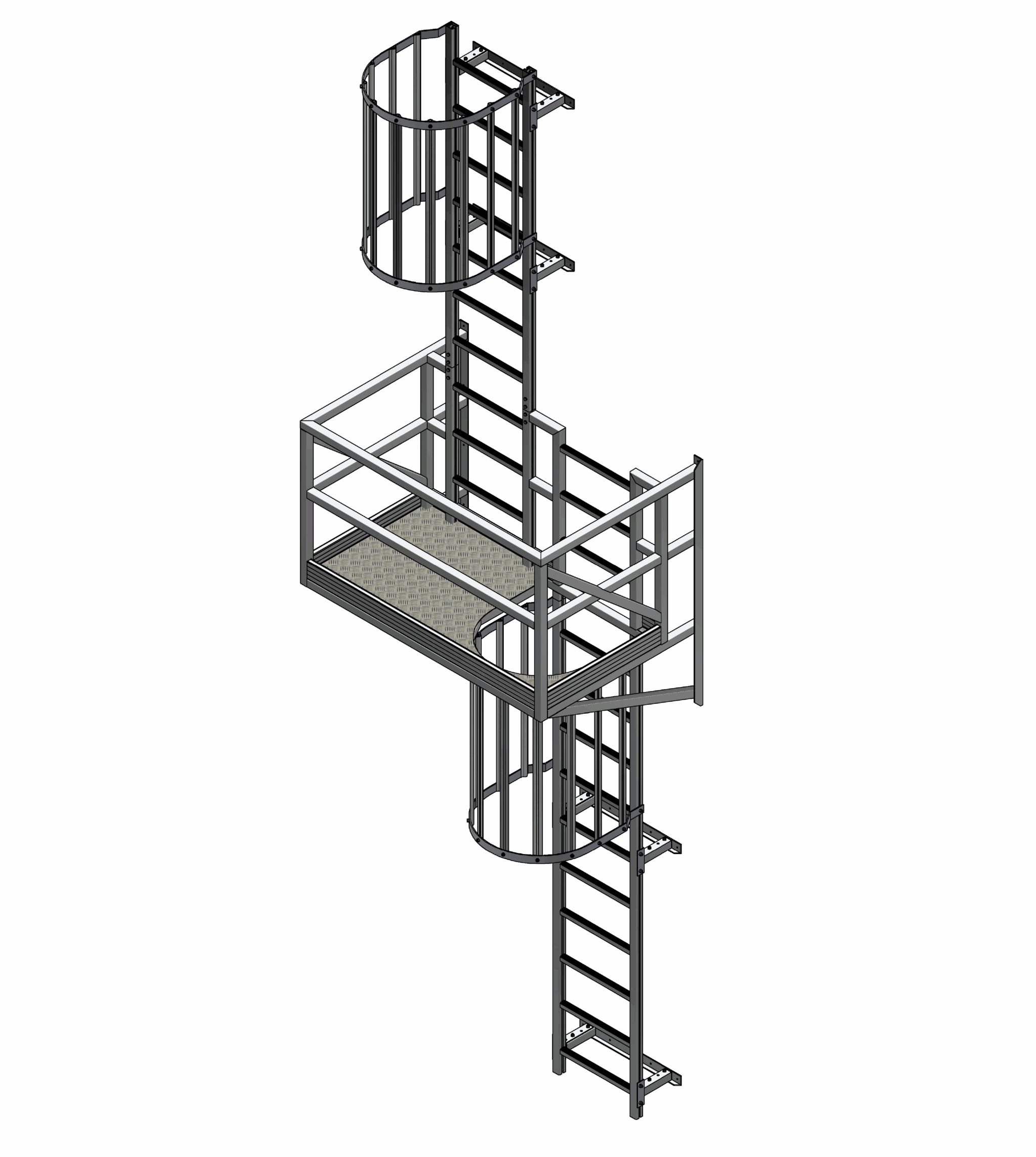

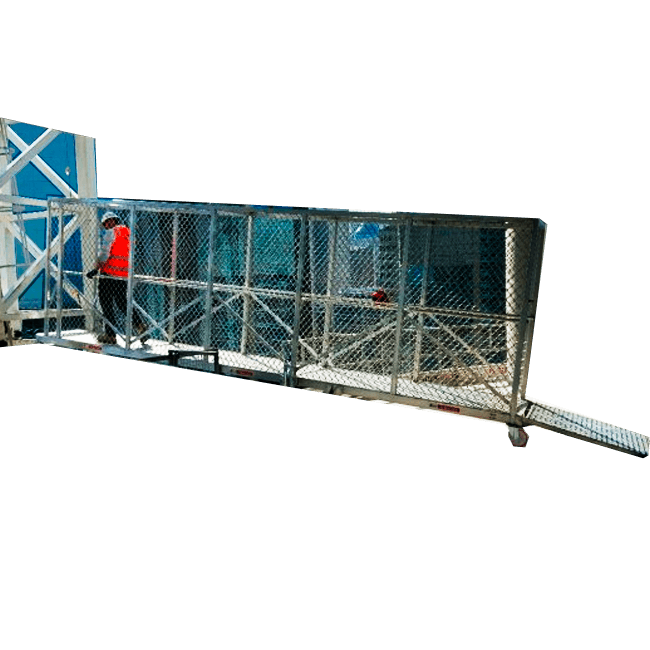

Intermediate landing for the Ladder;

a. To comply with Australian Standards, an intermediate landing will be required where the uninterrupted climb distance between the access points is greater than 6mL, SKU: 210435 – Silo Ladder Intermediate Landing.

Your components calculation is complete!

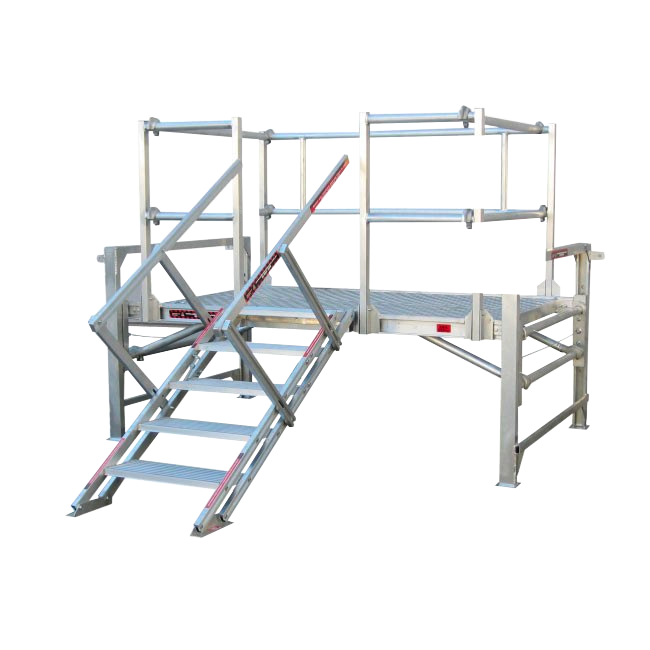

- Modular components are used to create any length ladder required

- Design your own using ladder extrusion, hoop guardrails & fixing brackets Landing platforms available for ladders 6m+ long

- CAD drawings available upon confirmation of ladder length & design

- Made to order

Selecting the correct components for your Caged Ladder requirements;

1. Length of the Ladder;

a. We have a range of available lengths listed.

b. The height of your ladder is measured from access point to access point + 1m. For example, say you are accessing a mezzanine level where the floor is 3m above the lower level, the length of ladder needs to be 4m

(3m + 1m = 4m).

c. Select the closest length from the list of available lengths, slightly longer if the exact length is not available so this can be cut down to suit the application.

d. If the length you require is longer than the available lengths, select the combination of lengths that leads to the least offcut and least number of joins required.

2. Joining/Mounting Hardware for the Ladder;

a. If you ladder length is longer than the available lengths and 2 or more sections are required to be joined together, you will required the SKU: 210268 – Silo Ladder Spigot Set (including hardware). One set is required per additional ladder section.

b. The ladder is mounted to the support surface with the use of SKU: 210200 – Silo Ladder Wall Mount Bracket. These are required at either end of the ladder and then every 3m along the length of the ladder from the bottom position. For a 3.6mL ladder, you will require 3 brackets.

3. Cage Components for the Ladder;

a. To comply with Australian Standards, the cage of the ladder needs to be positioned so that there is 2.1m of clearance between the bottom of the cage and access surface that personnel will be using to get onto the ladder. This is to ensure head height clearance for the user.

b. Additionally, the cage needs to extend 1m up above the upper access point.

c. To calculate this, using the mezzanine scenario as previous where the mezzanine level is 3m above the lower level; the length of the cage needs to be 3m + 1m – 2.1m = 1.9mL cage.

d. With this calculation complete, now calculate the number of hoops required to create the cage frame SKU: 210267 – Silo Ladder Hoop (including hardware). These are required top and bottom of the cage and then spaced every 2m from the bottom of the cage. In the case of the above calculation where the cage length is 1.9m, 2 hoops will be required.

e. Now calculate the Cage Extrusion required, SKU: 210266 – Silo Ladder Cage Extrusion /metre. As per the description this is supplied per lineal metre. There are 10 ‘slats’ around the hoop that form the cage. The calculation of the lineal metres of slats required is as follows, the length of the cage required (i.e 1.9m) multiplied by 10, this means 19LM of cage extrusion is required (1.9m x 10 = 19m).

Intermediate landing for the Ladder;

a. To comply with Australian Standards, an intermediate landing will be required where the uninterrupted climb distance between the access points is greater than 6mL, SKU: 210435 – Silo Ladder Intermediate Landing.

Your components calculation is complete!